Performance Characteristics

-

01High-Quality Screening+Efficient Multilayer Screen Design

01High-Quality Screening+Efficient Multilayer Screen Design

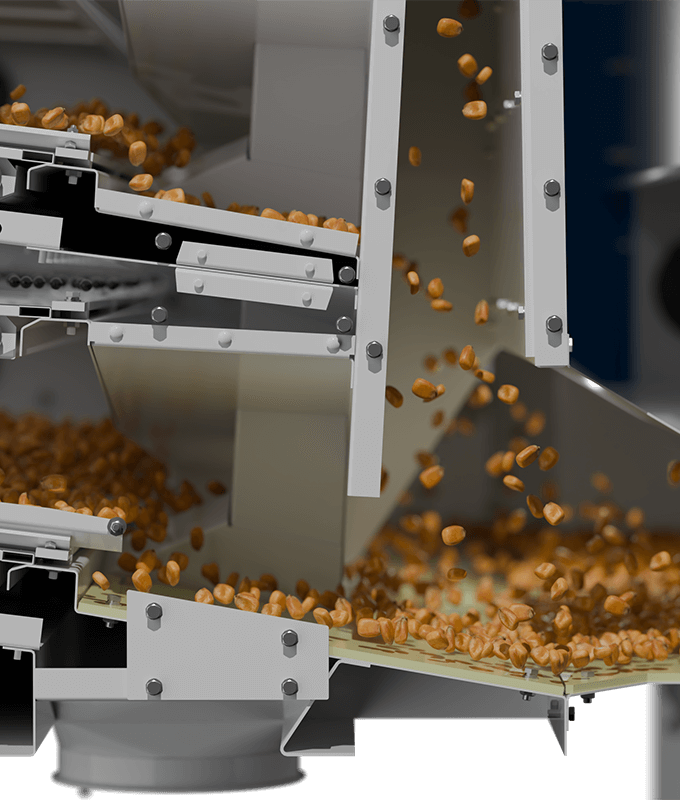

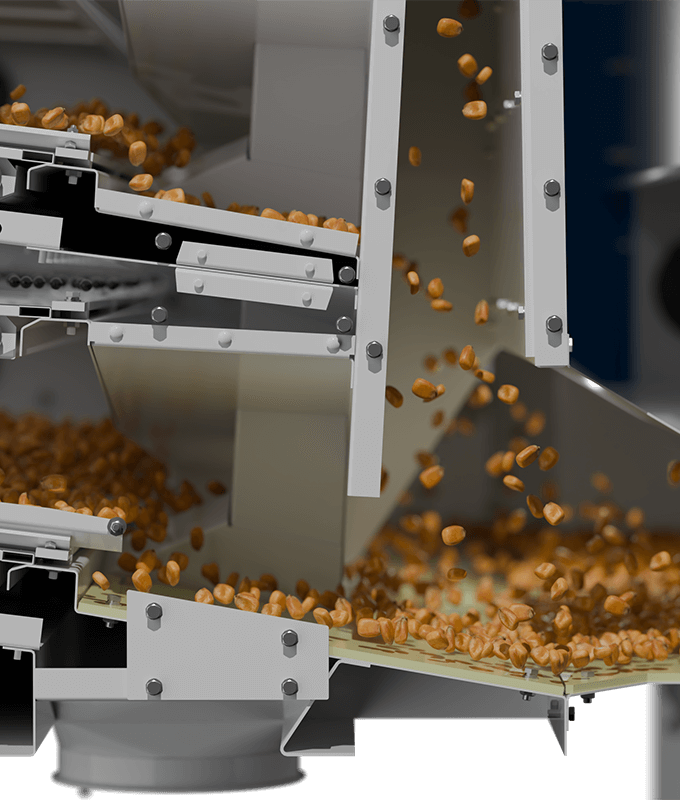

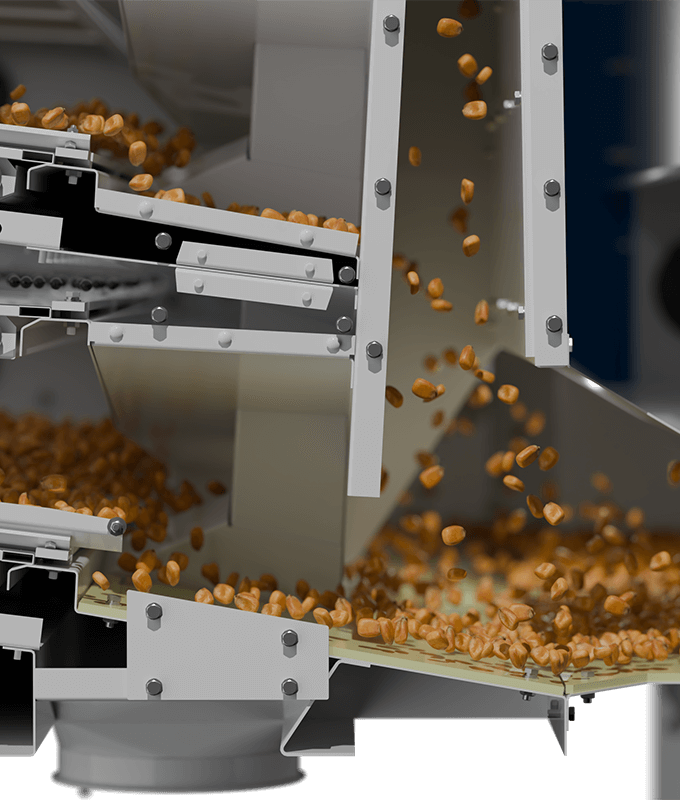

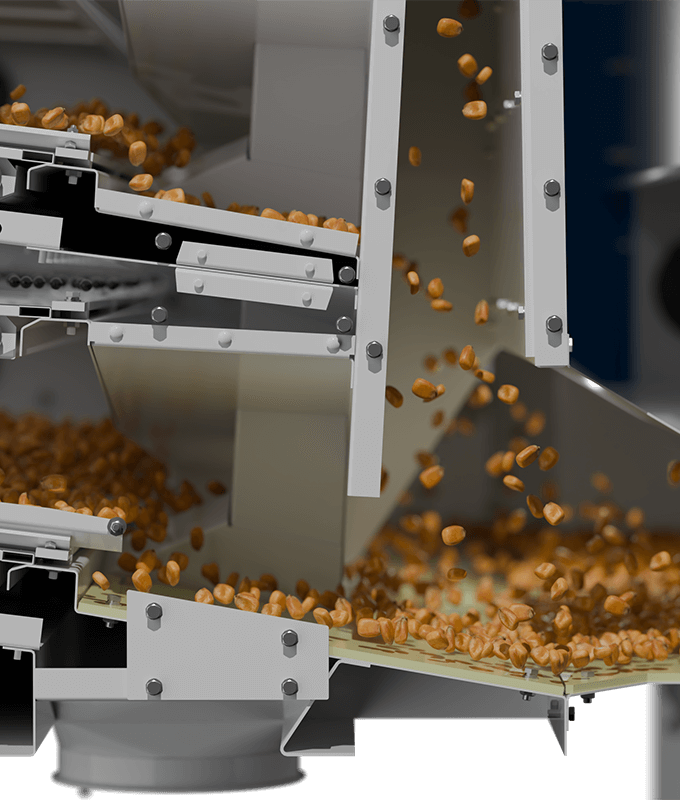

Our multilayer screens are connected in parallel, effectively doubling the screen area. This design reduces the bed depth, allowing impurities to pass through the screens more easily. As a result, screening efficiency is significantly improved, with a measured impurity removal rate exceeding 90%. This ensures both high screening quality and productivity, making it an ideal solution for precision and performance in your operations.

The screens rotate, causing materials to move in a spiral motion across the screen surface. This innovative design ensures precise and efficient screening of materials, meeting high-performance standards.

With a multi-point feeding design, the feeding area of the screen surface is increased by 50% to improve the screening quality further. -

02Improved Efficiency+The screens feature a sectional design, reducing screen replacement time from 15 minutes to just 5 minutes. This improvement makes the sifter especially suitable for applications requiring frequent screen changes, ensuring uninterrupted and efficient production.

02Improved Efficiency+The screens feature a sectional design, reducing screen replacement time from 15 minutes to just 5 minutes. This improvement makes the sifter especially suitable for applications requiring frequent screen changes, ensuring uninterrupted and efficient production.

Each screen weighs less than 11 kg, allowing for easy replacement by a single person. This design reduces labor intensity, minimizes the need for additional workers, and enhances overall work efficiency. -

03Loss Reduction+The standard stainless steel screens offer excellent wear resistance, with a service life that is 50% longer than wooden screen frames. This durability reduces replacement frequency and helps lower operational costs, ensuring long-term efficiency and reliability.

03Loss Reduction+The standard stainless steel screens offer excellent wear resistance, with a service life that is 50% longer than wooden screen frames. This durability reduces replacement frequency and helps lower operational costs, ensuring long-term efficiency and reliability.

The elastic cleaning ball is designed with high strength and wear resistance, offering exceptional durability. With a service life exceeding 15,000 hours, it lasts over 50% longer than natural rubber and silicone cleaning balls, ensuring reliable performance and reduced maintenance needs. -

04Intelligent Operation+Equipped with a safety monitoring sensor, the system continuously monitors the operation of the sifter body 24 hours a day. When a collision between the sifter body and the frame is detected, the motor is stopped via braking, preventing equipment damage and mitigating other safety risks

04Intelligent Operation+Equipped with a safety monitoring sensor, the system continuously monitors the operation of the sifter body 24 hours a day. When a collision between the sifter body and the frame is detected, the motor is stopped via braking, preventing equipment damage and mitigating other safety risks

Equipped with a self-cleaning system for the screen surface, the FAMSUN centrifugal sifter effectively prevents screen blockages. This feature ensures continuous cleaning of the screen, improving screening efficiency and supporting smooth, automated operation.

The inside of the sifter body and the feeding and discharging chute are designed to prevent accumulation, have no dead corners, reduce internal residue, and reduce manual cleaning.

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN